Our sustainability journey

The brewing process is resource-heavy and has large emission sources, from the agricultural emissions in the ingredients used, right through to the transportation of beer to customers. At Bluntrock we want to do everything we can to help future-proof our beloved industry, and our expansion has given us the opportunity to better our environmental efforts from more than one angle. We're going to try to be as transparent as possible throughout our journey.

Throughout our journey, we'll be chatting lots more about the sustainability of our new brewery, and how we're strategising as a team to make our operations greener. Read on to learn about our new carbon capture system.

First Co2 Recovery System installed in a cornish brewery

With the realisation that our impact was only going to grow with our expansion, it seemed only right to try and secure investments and start to implement strategies that would help us to minimise it.

Initially, the most obvious choice to us was the opportunity of carbon dioxide recovery - where the CO2 produced as a byproduct fermenting beer is captured, rather than letting it drift away into the atmosphere. Once captured, the CO2 is then cleaned, stored and re-used for use in carbonating the beer, in the packaging process and for purging tanks.

This creates a closed loop, effectively taking a waste by-product and streaming it back into the business for reuse.

The circular economy approach that carbon capture achieves resonates perfectly with our sustainability goals, so including this technology in our expansion became a top priority.

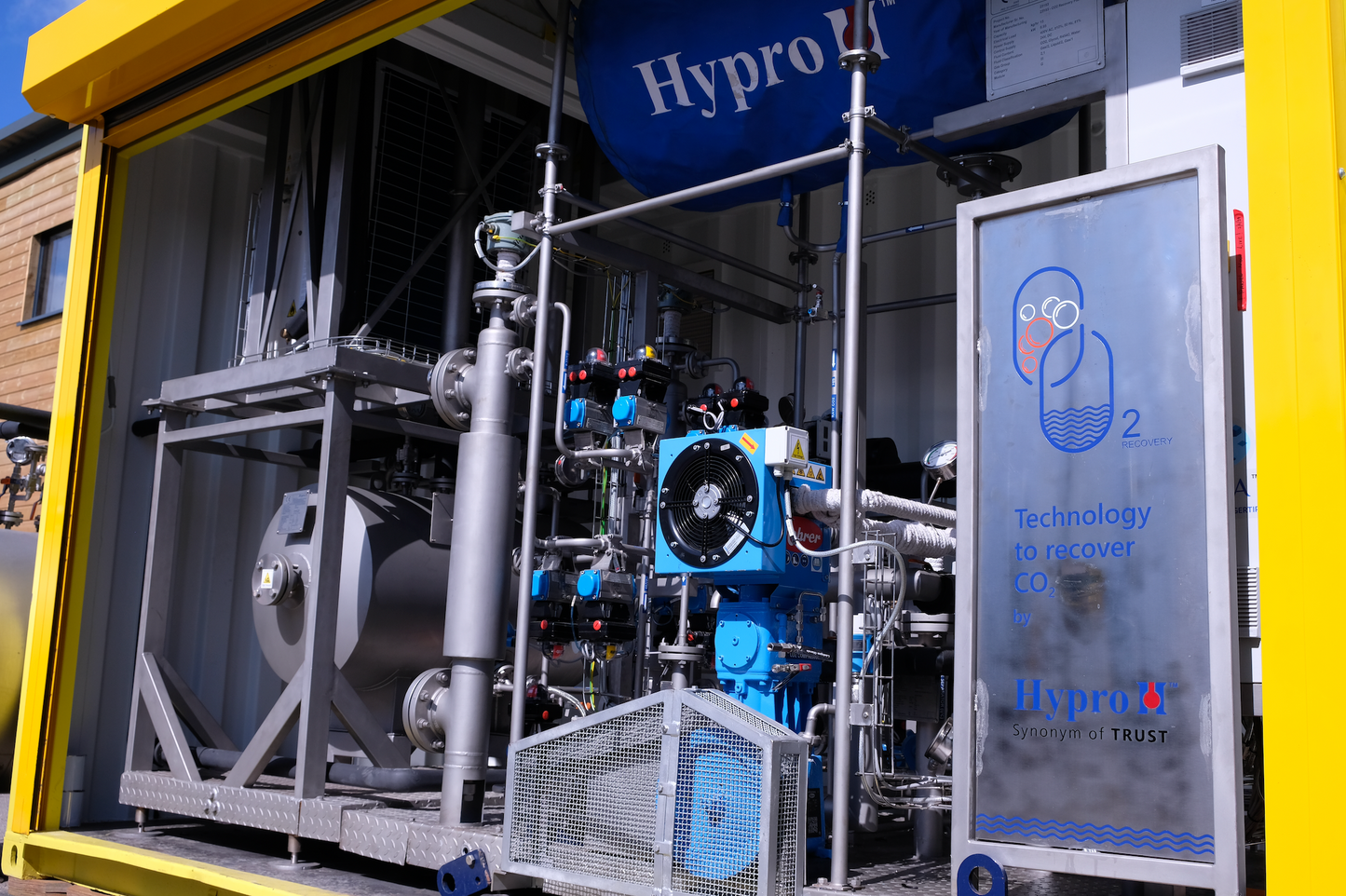

CO2 recovery systems are relatively new to the micro-brewing industry, having previously only been scoped for macro scale breweries, but the technology is achieving greater accessibility and effectiveness year on year. We were recommended the new HyCrC CO2 recovery system by the India based company Hypro; a compact, user-friendly solution for smaller craft breweries, which delivers a supply of 99.995% pure liquid CO2 at up to 15kg per hour! Learn more about our system from Hypro.

After arriving in the UK at the start of summer 2024, the new HyCrC system was commissioned by Brian, from SSV, and Anurag, one of the engineers from Hypro - see right. He flew all the way from Mumbai, India, to be here for the commissioning.

We’re delighted to say that we are the very first Cornish brewery to have one of these systems installed. Here's to a more sustainable brewing future here at Bluntrock!

Sign up to our newsletter to get the latest updates on our Sustainability journey!